March 11, 2025

By Brian Mehalic and Alex Jahp | Solar Tech Collective

How should an operations and maintenance (O&M) program be structured? What tasks need to be performed, and how frequently? These are questions that the PV industry has been struggling with for years, without a definitive resource, and mostly relying on the limited instructions provided by manufacturers. That changed in 2023 with the publication of NFPA 70B, Standard for Electric Equipment Maintenance, as a consensus standard.

70B has been the NFPA’s primary document covering electrical equipment maintenance since 1975, but previously was a “recommended practice.” Now it is a “standard” meaning that the language in the document has changed from “should” to “shall.” This means that it now can be adopted and enforced, be referenced in contracts, and used with confidence in the absence of manufacturer instructions.

NFPA 70B’s purpose is to “protect people, property, and processes from failures, breakdowns, or malfunctions” through the creation and execution of an Electrical Maintenance Program (EMP). It works in conjunction with NFPA 70 National Electrical Code and NFPA 70E Standard for Electrical Safety in the Workplace to ensure that electrical work is performed safely, that equipment is properly installed, and that it is maintained properly going forward. NFPA 70E requires that electrical equipment be properly maintained, and following NFPA 70B is an excellent way to comply.

What systems are covered?

NFPA 70B is not applicable to single-family dwellings or plug-in loads — its scope is electrical, electronic, communication systems, and equipment “typical of those installed for industrial plants, institutional and commercial buildings, and large multifamily residential complexes.”

It provides tasks, tests, and intervals for nearly all equipment found on a typical C&I or utility-scale PV or energy storage site. This includes switches, panelboards, breakers and fuses, cables and conductors, transformers, and more. PV systems even get their own chapter!

It is crucial to note that 70B does not supersede manufacturer instructions, nor does it specify how to perform the tasks and tests or exactly how to evaluate results. This information can be found in manufacturer documentation, ANSI/NETA Standard for Maintenance Testing Specifications for Electrical Power Equipment and Systems, and the various parts of IEC 62446.

A properly run O&M program needs a lot more than just a list of what needs to be done and when; it requires trained technicians, a safety program, and processes for documentation. NFPA 70B provides guidance on this and more — it offers a framework that system owners, system operators, and third-party contractors can adopt to create comprehensive, efficient O&M programs that will lead to better-performing assets and safer working conditions.

Enforcement and cost

Two immediate concerns arise when discussing NFPA 70B: enforcement and cost.

You can breathe a sigh of relief — your local AHJ isn’t likely to adopt and start enforcing NFPA 70B anytime soon. However, it is likely that this standard will begin to be adopted by the industry and will be referenced in contracts. Beyond contractual requirements, every company performing maintenance work on large-scale PV sites should consider structuring their operations around 70B as it creates a scalable program that protects people and assets, and early adoption of a standard helps position your company as a leader in the field.

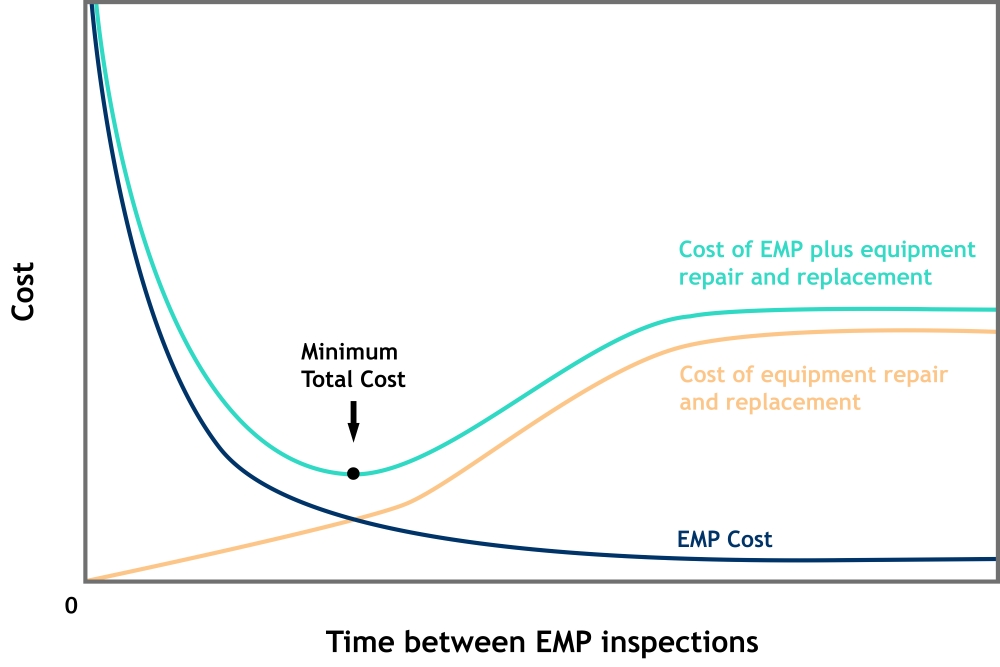

A formal Electrical Maintenance Program may sound like a new burden to some companies, but the reality is that 70B provides a structure for work that is already required to be performed. Not maintaining electrical equipment isn’t an option, and at the bare minimum the manufacturer’s instructions must be followed. A properly structured Electrical Maintenance Program seeks to find the correct balance between reactive and preventive maintenance that minimizes total costs and disruption to operations. 70B provides flexibility for EMP administrators to modify maintenance intervals based on maintenance history, continuous monitoring systems, and predictive maintenance techniques to optimize the program.

Structure a program around NFPA 70B

The standard itself provides requirements for what a program should look like, but not a roadmap of how to get there. The steps to actually build an EMP structured around the 38 chapters and 13 annexes of NFPA 70B are more involved and need to be tailored to your particular organization and projects.

Based upon Solar Tech Collective’s experience helping companies build their O&M programs, we have developed a series of basic steps for building an O&M program structured around 70B:

- Gathering and reviewing documentation.

- Surveying and analyzing equipment and maintenance history.

- Determining maintenance tasks and intervals.

- Developing procedures.

- Determining personnel and training requirements.

- Developing policies and systems for documentation and tracking.

- Developing systems for continuous improvement.

It is an exciting time in the O&M space: Years of data and experience have shown the value of investing in quality maintenance programs that more closely resemble those in the rest of the electrical industry. This includes more formalized policies, procedures, documentation, safety requirements, and personnel requirements that help ensure that PV and energy storage systems are safe, reliable, and profitable. Get ahead of the curve by learning more about NFPA 70B and how to create an effective Electrical Maintenance Program.

Brian Mehalic and Alex Jahp are with The Solar Tech Collective. For more on creating an Electrical Maintenance Program, take Solar Tech Collective’s class NFPA 70B: A New Standard for Electrical Equipment Maintenance. Visit solartechcollective.com to learn more.

Tags: standards

Source link